DEGREES IN Welding/Fabrication

Welding/Fabrication Diploma

By the Numbers

Why Choose This Program

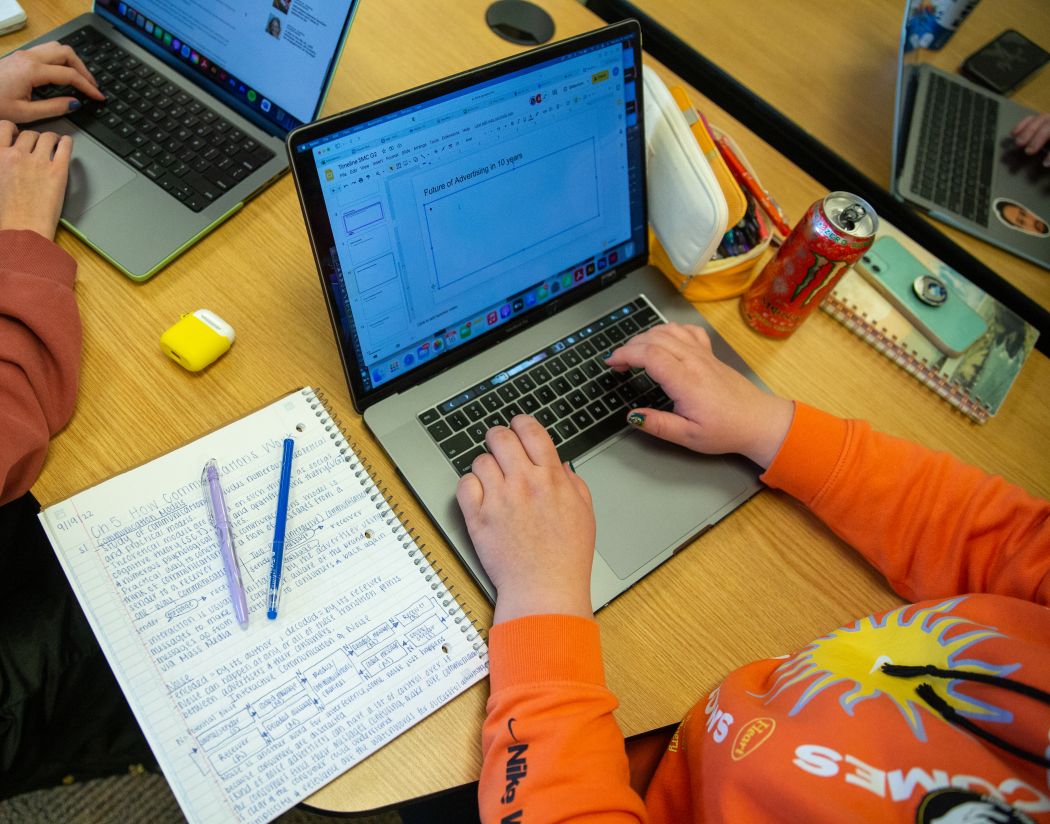

Students in the SCTCC welding program learn a variety of techniques, including Shielded Metal Arc Welding, Oxy-Acetylene Welding and Brazing, Gas Metal Arc Welding, Gas Tungsten Arc Welding, fuel gas, and plasma cutting.

Our students are even equipped with skills of metallurgy, fabrication and equipment, automated machining, CADD, blueprint reading, and safety procedures.

To ensure upmost quality for every student, all welds will be made to industry standards using the AWS D1.1 Structural Code and AWS D1.3 structural welding code-sheet steel. Welds will be done in all positions and guided bend tests will be made to check weld quality.

Placement rate from self-reported data of graduates available for work in field of study up to one year post graduation. Wage data is from Minnesota Dept. of Employment and Economic Development (DEED). SCTCC Consumer Information.

From Degree to Career

When you choose the Welding program at SCTCC, you’ll gain skills that will directly transfer to the workplace. There are several employers in the St. Cloud area that are ready to hire welders, including CWMF Corp, Park Industries, New Flyer, DCI. Inc., Rotochopper, and more.

At SCTCC we teach students the skills needed to succeed in the workforce. Our students can demonstrate the ability to read and interpret blueprints and codes, use critical thinking skills and apply mathematics to solve welding problems, and determine materials properties to insure safe handling and proper disposal of hazardous materials.

To ensure quality in their work, graduates of our welding program understand how to select appropriate welding technology and techniques to properly demonstrate welding ability with GMAW, GTAW, FCAW, SMAW, OFW, and Robotic Welding.

After graduation, students can utilize appropriate forms of communications to effectively and efficiently communicate with costumers, co-workers, and supervision, apply critical thinking and decision-making processes to technical problem solving, and demonstrate the ability to schedule, plan, and manage time effectively to maintain a good attendance record.

Quick Glance

- Demonstrate the ability to read and interpret blueprints and codes.

- Use critical thinking skills and apply mathematics to solve Welding problems.

- Select appropriate welding technology, techniques, and be able to properly demonstrate welding ability with GMAW, GTAW, FCAW, SMAW, OFW, and Robotic Welding.

- Determine materials properties to insure safe handling and proper disposal of hazardous materials.

- Use appropriate forms of communications to effectively and efficiently communicate with costumers, co-workers and supervision.

- Apply critical thinking and decision-making processes to technical problem solving.

- Demonstrate the ability to schedule, plan, and manage time effectively so you are able to maintain a good attendance record.

View all program learner outcomes

Types of Careers

With a degree in welding and fabrication from SCTCC, graduates have opportunities in a variety of areas for their future careers. Students have worked with welding, fabrication, structural steel, energy, and plant maintenance.

Our students have even utilized their skills to work with pipe fitting, plumbing, and sales. With so many career routes students can go through, our SCTCC graduates are certain to find a job that is right for them.

Potential Employers

At SCTCC, we teach students a variety of skills to make them highly employable. Students have found employers in stainless steel tank fabrication, structural steel fabrication, power plant construction, and pipe fitting for medical grade equipment.

Our graduates have even found careers working with pipe fitting for petroleum, equipment and robotics sales, self-employment and entrepreneurship, transportation manufacturing, agricultural manufacturing and repair, and offshore drilling construction.

A day in the life of an SCTCC welding and fabrication graduate consists of working for the successful company, Park Industries. Students have utilized their skills in structural steel to excel in their career.

Quick Glance

Types of Careers

- Welding

- Fabrication

- Structural Steel

- Energy

- Plant Maintenance

- Pipe Fitting

- Plumbing

- Sales

Potential Employers

- Stainless steel tank fabrication

- Structural steel fabrication

- Power plant construction

- Pipe fitting for medical grade equipment

- Pipe fitting for petroleum

- Equipment and robotics sales

- Self-employment/entrepreneurship

- Transportation manufacturing

- Agricultural manufacturing and repair

- Off shore drilling construction

From leading companies like New Flyer and DCI Inc., SCTCC graduates have found jobs that fit their career goals. Students have the opportunity to utilize their skills with a variety of employers, allowing them to find the right match for them.

Our students have even worked with CWMF Corp, Park Industries, Rotochopper, Polar Tank Trailer, and Legacy Building Solutions.

Quick Glance

- CWMF Corp

- DCI Inc.

- Park Industries

- New Flyer

- Rotochopper

- C4 Welding Inc.

- Ben's Structural Fabrication

- Polar Tank Trailer

- Legacy Building Solutions

- Towmaster Trailers

American Welding Society (AWS) SENSE Program

For students who are looking to further their education, graduates of the SCTCC welding and fabrication program can transfer their credits to the Applied Engineering major at Bemidji State University.

Ready to Take the Next Step?

Are you ready to learn more about the Welding program and being a student at SCTCC?

Fill out this form to receive useful information that's specific to your program.

- Call us at 320-308-5089

-

Email us at recruitment@sctcc.edu

- On campus Monday-Friday, 8 a.m.-4:30 p.m.

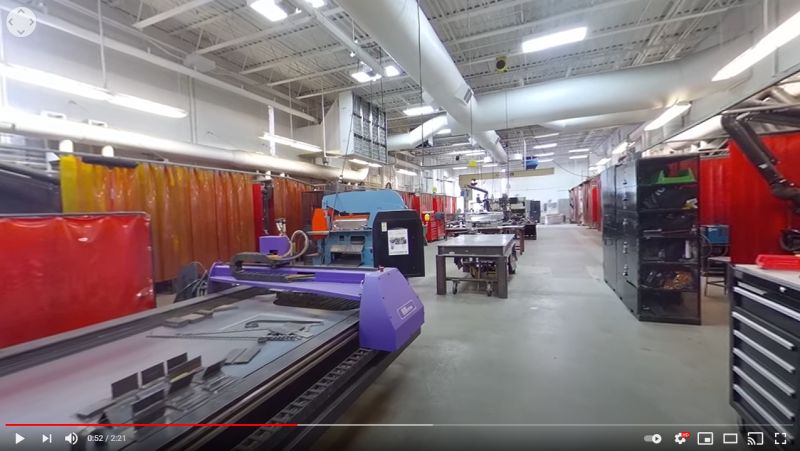

Visiting campus is an excellent opportunity to learn about SCTCC programs, the application process, and tour the state-of-the-art-labs and classrooms.

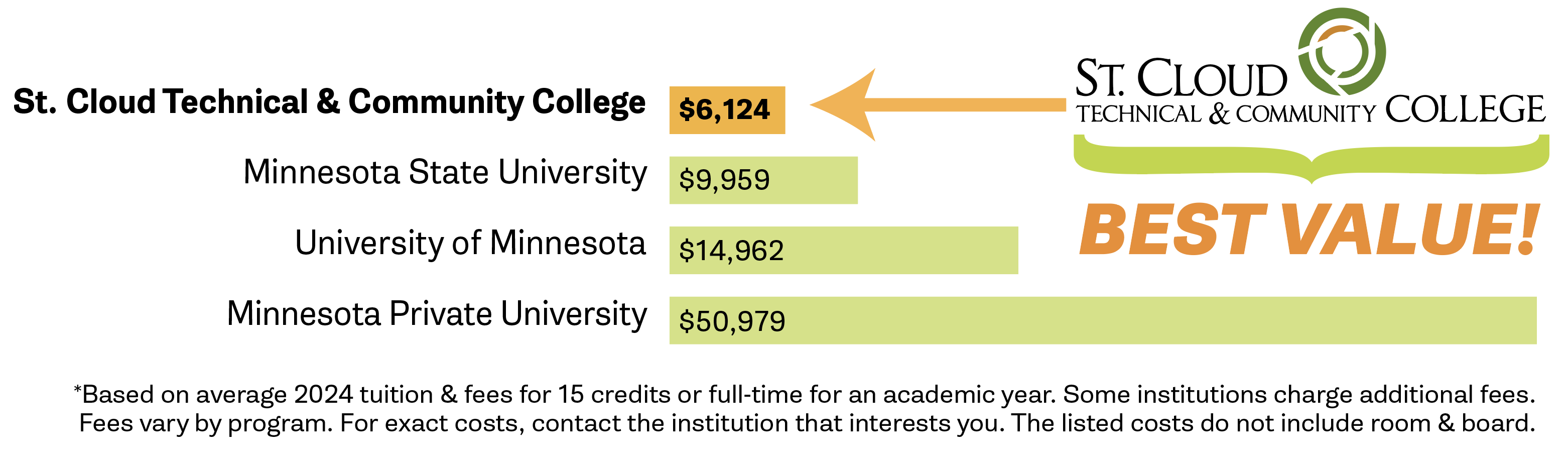

Paying for College

Students choose SCTCC for a lot of reasons, but saving money is one reason we hear from almost every student at SCTCC. We’ve got a breakdown of the costs for the program, along with information on financial aid and scholarships.

Apply just once and you are considered for all eligible SCTCC scholarships.

Program Info for Current Students

SkillsUSA - Welding

SkillsUSA is a partnership of students, teachers and industry working together to ensure America has a skilled workforce. SkillsUSA helps each student excel and provides educational programs, events and competitions that support career and technical education (CTE) in the nation’s classrooms.

Good Stuff

Dahlberg's Capstone Panther on its way to Tracy

Jasslyn Dahlberg's Panther Project is Ready for a Close-up

SCTCC, AgCentric, & Advanced Manufacturing Center Host HS Teachers

More Like Welding/Fabrication

Robotics & Industrial Controls