DEGREES IN Mechanical Design Engineering Technology

Mechanical Design Engineering Technology Associate of Applied Science

By the Numbers

Mechanical Design Engineering Technology Diploma

By the Numbers

Why Choose This Program

Mechanical designers help engineers with the design and development of new products and tools and updating present equipment.

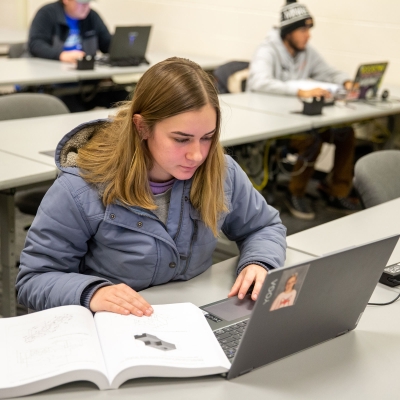

Students in our program will be immersed in the product design process. This includes the selection of the manufacturing processes and materials, design and stress calculations, applying geometric dimensioning and tolerancing, finite element analysis, cost, and safety.

Graduates of our program will be ready to start their career after learning how to create designs using SCTCC’s state-of-the-art computer hardware, the latest 2D drawing/design, 3D modeling, and computer-aided-manufacturing software.

Placement rate from self-reported data of graduates available for work in field of study up to one year post graduation. Wage data is from Minnesota Dept. of Employment and Economic Development (DEED). SCTCC Consumer Information.

From Degree to Career

When you choose the Mechanical Design Engineering Technology program at SCTCC, you’ll gain skills that will directly transfer to the workplace. With your degree, you can build your career in medical equipment, plastics, heavy equipment, custom accessories for trucks, ATVs, and diesel and agriculture equipment, as well as many other career fields.

At SCTCC, we teach our students the skills needed for the workforce. Our students learn how to create parts, assemblies, and drawings for a variety of applications using 2D and 3D CADD software.

Graduates from our Mechanical Design Engineering Technology program can design a product from the early stages of the concept to a completed set of drawings ready for manufacturing. Students at SCTCC learn how to use industrial 3D printers to create design prototypes and create geometry that you will use to cut out or etch in different materials using a CO2 laser and a plasma cutter.

To ensure our graduates are prepared for their future employment opportunities, we teach students the basics of Computer-Aided Design Manufacturing (CADM) using Mastercam software and a CNC lathe and router to create real parts.

Quick Glance

- Create 2D and 3D parts, assemblies and drawings for a variety of different applications.

- Design a product from concept to a completed set of drawings ready for manufacturing.

- Learn how to use industrial 3D printers to create design prototypes.

- Create geometry that you will cut out or etch in different materials using a CO2 laser and a plasma cutter.

- CNC lathe and router with Mastercam software.

View all program learner outcomes

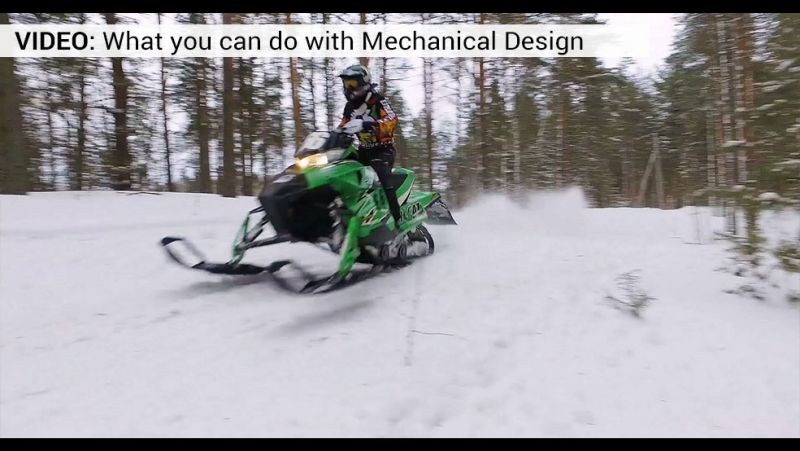

Graduates from our Mechanical Design Engineering Technology degree have a variety of future career opportunities. In the state of Minnesota, ATV and snowmobile design and manufacturing are very popular. However, that is just one of the various career options our students can pursue.

Students can also find potential job options designing and manufacturing medical equipment, plastics, heavy equipment, and custom accessories for trucks, ATVs, and diesel market.

You can even find SCTCC graduates working with after-market auto and truck equipment, sporting equipment (i.e. skateboards), and agriculture equipment, as well as many other career fields.

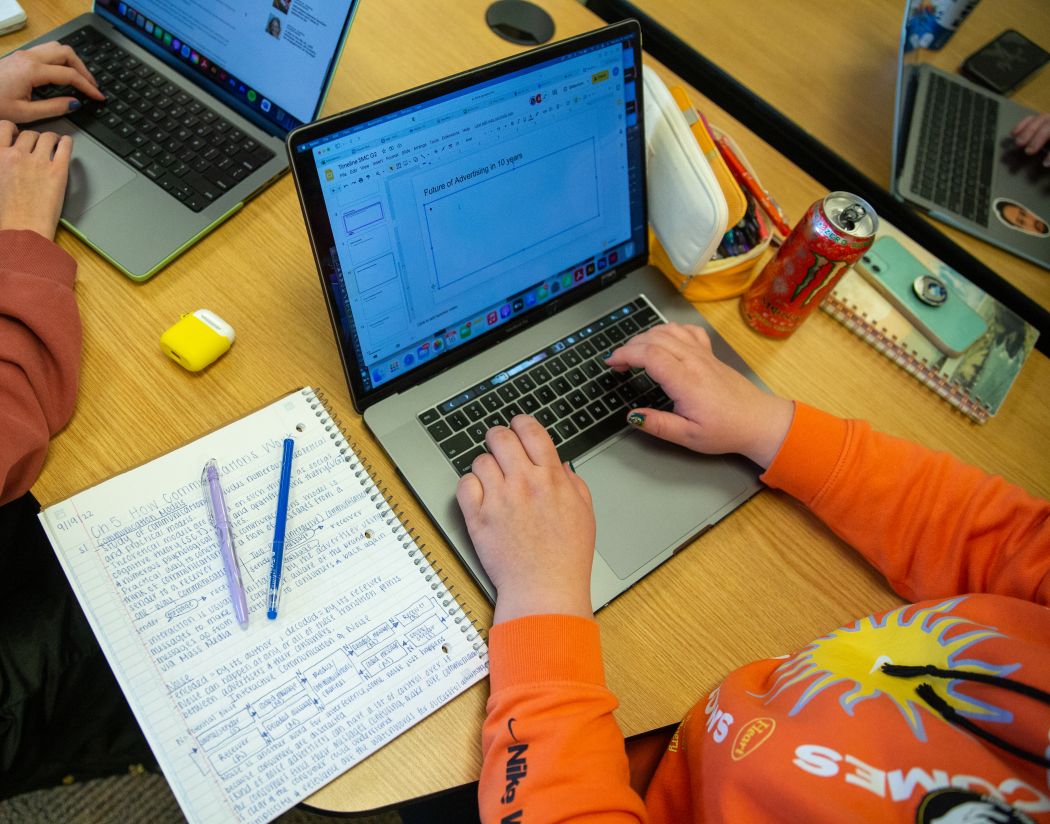

A day in the life of an SCTCC graduate from our Mechanical Design Engineering Technology program often consists of creating production drawings and designing products using 2D and 3D design software. They also find themselves working with engineers, machinists, welders, assemblers, and quality control in the manufacturing of products.

Quick Glance

There are a wide variety of products you can find yourself designing and modifying, below are just a few of those products:

- ATV/snowmobile design & manufacturing

- Medical equipment

- Plastics

- Heavy equipment

- Custom accessories for trucks, ATVs, diesel market

- After market auto/truck equipment

- Sporting equipment (for example: skateboards)

- Agriculture equipment

- Machines that are used to manufacture other products or moving product during manufacturing

- Valves for water distribution, oil & gas, mining, pulp & paper, etc.

- Tanks for pharmaceuticals, food & dairy, beverage, cosmetics, etc.

- Industrial kitchen equipment

SCTCC not only prepares students for the workforce, but also for further academic goals. At SCTCC, we have an excellent 2+2 arrangement with Bemidji State University for a bachelor’s in Applied Engineering. Students in Mechanical Design Engineering Technology are more than welcome to pursue this program.

Ready to Take the Next Step?

Are you ready to learn more about the Mechanical Design Engineering Technology program and being a student at SCTCC?

Fill out this form to receive useful information that's specific to your program.

- Call us at 320-308-5089

-

Email us at recruitment@sctcc.edu

- On campus Monday-Friday, 8 a.m.-4:30 p.m.

Visiting campus is an excellent opportunity to learn about SCTCC programs, the application process, and tour the state-of-the-art-labs and classrooms.

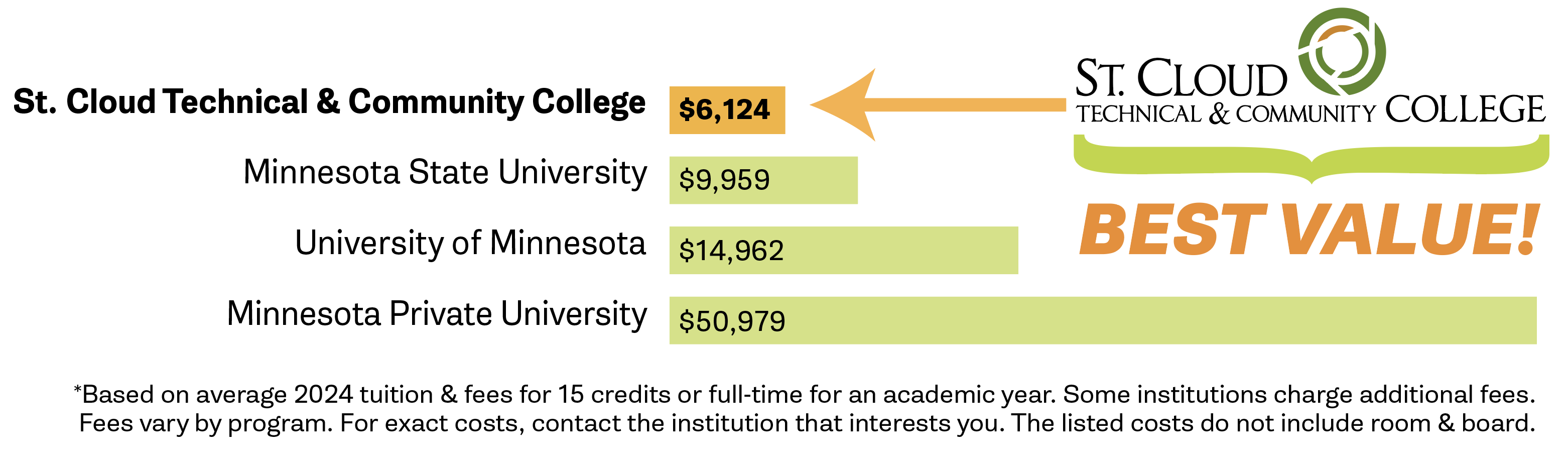

Paying for College

Students choose SCTCC for a lot of reasons, but saving money is one reason we hear from almost every student at SCTCC. We’ve got a breakdown of the costs for the program, along with information on financial aid and scholarships.

This program requires laptops. Find information on required specifications

Apply just once and you are considered for all eligible SCTCC scholarships!

Program Info for Current Students

The Mechanical Design Engineering Technology program has a laptop requirement.

Find information on required laptop specifications for the program.

Our Mechanical Design Engineering Technology program has a student chapter of the American Design Drafting Association (ADDA), which is a professional organization that supports the drafting and design profession.

Club members meet on a monthly basis to organize the activities for the year, which include the following:

- Highway clean up/fall social

- Fundraising activities

- Donation of time/money to community organizations

- Spring manufacturing trip

- Spring social

The spring manufacturing trip is a fun and educational trip that is 4-6 days long and allows students to tour manufacturing facilities. This trip is planned by the club members, with oversite from the advisors. Past trips have been to companies like Polaris, Arctic Cat, and Caterpillar in Illinois, John Deere in Iowa, auto manufacturers in Michigan, Kentucky, and Ohio, and Harley Davidson and Milwaukee Forge in Wisconsin.

Mechanical Design Instructor

Good Stuff

SCTCC, AgCentric, & Advanced Manufacturing Center Host HS Teachers

Time Capsule Captures Students' Expertise

SCTCC Celebrates: Advanced Manufacturing Center, 75th Anniversary, Cyclones Volleyball

More Like Mechanical Desing Engineering Technology